Development of Logistics Drones: The Importance of Airspace Optimization and Testing

Development of Logistics Drones: The Importance of Airspace Optimization and Testing

Aeronext is engaged in drone research and development, with a particular focus on multicopters specialized for logistics applications. By optimizing various aerodynamic characteristics, Aeronext pursues efficient and stable flight performance.

Differences Between Logistics-Specialized Multicopters and General Multicopters

First, logistics-specialized multicopters differ from general multicopters commonly used for aerial photography and other purposes in how they move during flight. General multicopters perform various maneuvers, including hovering, vertical and lateral movements, and sharp turns. Even if aerodynamic design is not heavily emphasized, stable flight can be achieved as long as the flight controller functions properly.

In contrast, the primary objective of a logistics-specialized multicopter is efficient transportation. Since most missions involve sustained forward flight to a destination, the aircraft spends more time flying forward than hovering. Furthermore, because long-distance travel is required, flight speeds inevitably become higher. As speed increases, aerodynamic effects become more significant, making aerodynamic performance during forward flight critically important.

At Aeronext, research and development focuses on maximizing aerodynamic performance during forward flight. By reducing air resistance and using energy efficiently, we aim to extend both flight time and flight range.

Drone Development Approach: From Trial and Error to Simulation

In conventional drone development, prototypes are often built first and flown to collect real-world data. For small drones, costs are relatively low, making iterative improvements through trial and error feasible. However, for large drones, prototype manufacturing costs are substantial. If a prototype fails to deliver the expected performance, significant time and financial resources may be lost.

Similar to aircraft development, Aeronext does not begin by immediately manufacturing a full-scale aircraft. Instead, we adopt a step-by-step validation process, verifying performance at each stage. This approach reduces risk while enabling the rapid development of high-performance aircraft.

Three Key Validation Methods in Drone Development

In Aeronext’s development process, the following three validation methods play a critical role:

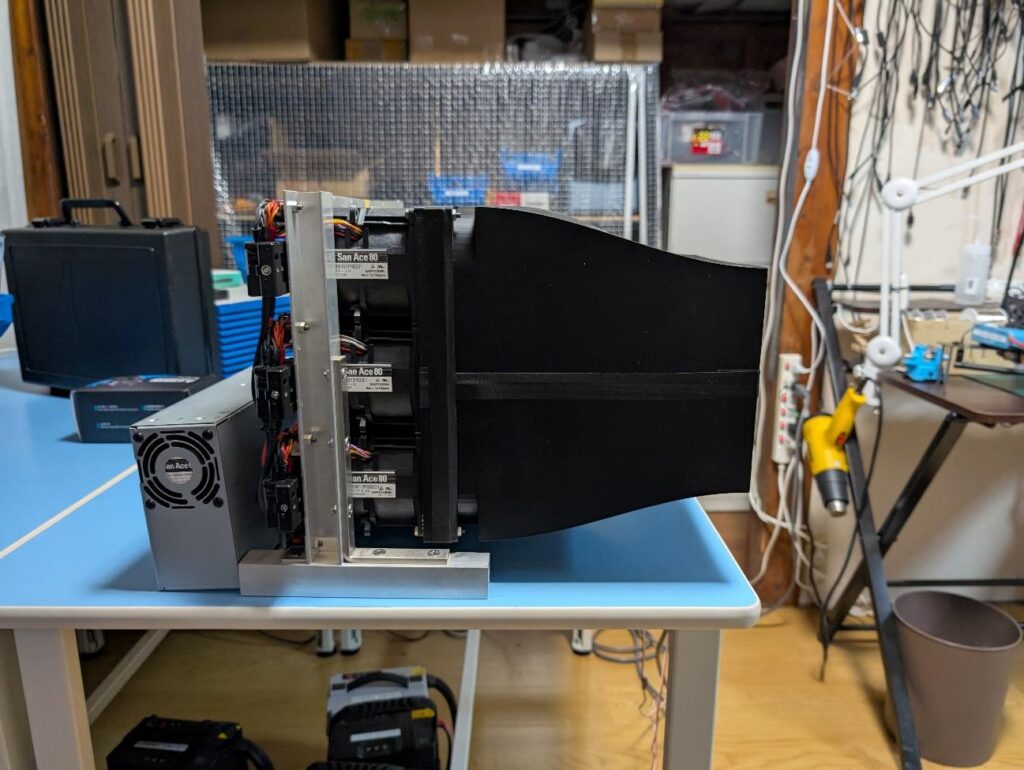

1. Wind Tunnel Testing

Wind tunnel testing is one method used to evaluate aerodynamic characteristics. While testing can be conducted at full scale, small-scale model aircraft are often used to assess aerodynamic performance. This allows aerodynamic characteristics to be verified and fed back into the design process at minimal cost, without fully manufacturing the actual aircraft.

Aeronext operates both a compact in-house wind tunnel (exit dimensions: 240 mm × 240 mm) and a large low-speed wind tunnel (exit dimensions: 2,000 mm × 1,000 mm), enabling a wide range of experimental evaluations.

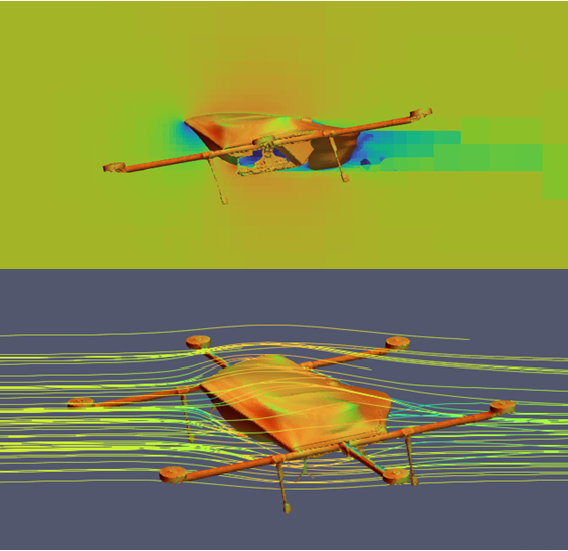

2. CFD Analysis

Computational Fluid Dynamics (CFD) analysis is a method of simulating fluid flow using computer-based calculations. Unlike wind tunnel testing, CFD does not require the creation of physical models, allowing for cost reduction and rapid evaluation.

At Aeronext, various fluid behaviors are simulated and used in conjunction with wind tunnel testing to achieve highly accurate designs. CFD also enables the testing of multiple aerodynamic scenarios, making it possible to identify improvements related to drag and aerodynamic moments smoothly during the early design stages.

3. Flight Testing

Finally, flight tests are conducted using scale models. By flying aircraft designed based on wind tunnel and CFD data, the gap between theory and real-world performance can be evaluated. Data collected during flight testing confirms whether predicted performance is achieved in practice, and designs are adjusted as necessary.

Aeronext’s Development Policy: Efficient and High-Performance Aircraft Design

At Aeronext, we emphasize combining staged validation methods rather than immediately building a full-scale aircraft. This approach is particularly effective for large aircraft, where early validation using scale models provides significant benefits.

Through wind tunnel testing, CFD analysis, and flight testing, aerodynamic characteristics are thoroughly verified. This enables the development of high-performance aircraft in a short timeframe while keeping costs under control.

By establishing this process, Aeronext aims to lead innovation in drone technology for the logistics sector.